Like all Personal Protective Equipment (PPE), you should regularly maintain and clean Clogger chainsaw pants and chaps to ensure that they remain fully functional. Regular maintenance will also extend the life of your Clogger chainsaw protective apparel.

Clogger products use a range of advanced textiles and fibres that have various finishes and coatings. These all have different properties that need to be considered and understood carefully.

This guide provides users of Clogger chainsaw protective apparel comprehensive advice on how to clean, maintain and inspect your Clogger gear so that you get the most out of your investment.

Looking for a quick guide? Check out this post.

- 1. Understanding the Materials Used

- a. Chainsaw Protective Fabric

- b. Outer Materials

- 2. Washing

- a. Pre wash

- b. Choosing the right laundry detergent

- c. Washing machine settings

- 3. Drying

- 4. Storage

- 5. Product Specific Instructions

- Zero Trousers

- Ascend Trousers

- DefenderPRO Trousers

- Defender Trousers (New Zealand / Australia / Japan only)

- Zero Chaps

- DefenderPRO Chaps

- C8 Chaps

- Fire Resistant (FR) pants – Wildfire and Arcmax

- 6. Inspection and Maintenance

- a. Rips and tears

- b. Burns

- c. Damaged seams

- d. Zips

- d. Chaps fastenings

- 7. Retirement of Chainsaw Pants and Chaps

- 8. Conclusion

1. Understanding the Materials Used

This section will look at factors to consider when you need to clean Clogger chainsaw pants and chaps based on the different materials used from the chainsaw fabric through the outers and coatings.

a. Chainsaw Protective Fabric

Maintaining the chainsaw protective fabric inside is critical to the effective functioning of your Clogger chainsaw pants or chaps.

There are two main risks to Clogger chainsaw fabric when washing.

Risk 1: Damage from agitation

Chainsaw protective fabrics have loosely woven or knitted fibres that can easily pull out with chainsaw contact. The ends of the fibres get caught in the seams holding the garment together. Therefore, this unique construction does mean that individual fibres are susceptible to migrating out of the normal structure during washing action.

This is why Clogger wash instructions specify a gentle machine wash. For instance, “permanent press” and why we say “Do not tumble dry”. Clogger chainsaw protective fabric is engineered to withstand repeated, regular washing without damage when using gentle agitation. Excessive or vigorous agitation may damage the chainsaw protective fibres.

Risk 2: Damage from heat

Clogger chainsaw protective products use three types of chainsaw protective fabrics with different tolerances to heat. Only Arrestex HP is susceptible to damage from heat during the laundering process. Arrestex HP is a proprietary Clogger fabric that includes a high percentage of cut resistant, ultra-high molecular weight polyethylene (UHMWPE). HP stands for “High Performance” and while this fabric performs exceptionally well for chainsaw cut-resistance it cannot tolerate high temperatures. The melting point of UHMWPE is approx 140°C (285°F) but it starts to shrink at 70°C (160°F). A hot wash, and definitely a hot tumble dry, may approach this temperature, which is why we specify ‘warm’ wash only.

b. Outer Materials

This is the next major component of chainsaw protective garments.

Clogger products use a variety of outer fabrics depending on the intended use of the garment. Pants or trousers use softer, more comfortable fabrics than chaps.

Virtually all fabrics will shrink a little after the first couple of washes and this is normal. The standard for chainsaw protection stipulates a maximum shrinkage rate of 6%. However, most fabrics used in Clogger products have a shrinkage rate of between 0 and 4%.

i. Non fire resistant fibres

The outer fabrics used in our non-fire resistant style trousers are made from polyester or nylon. The challenge with synthetic fibres is that they are hydrophobic and repel water but attract oils that cause odor. Most laundry detergents are designed for hydrophilic fabrics like cotton. Using a specialist detergent for synthetic fibres is a good idea. These detergents separate the oils from the synthetic fibres. Good options are Win Detergent and Grainger’s Performance Wash.

ii. Fire resistant fibres

Clogger Arcmax Gen3 pants and chaps use a blend of fire resistant fibers. These fibres provide flame and arc resistance. Contaminants like fuel and oil will affect the fire-resistant qualities so it is very important that these garments get washed regularly.

The fibres used in the Arcmax Gen3 fabric are inherently FR. They are not treated to make them FR. There is a perception that FR treatments can wash out. This may be correct for some cheap products out of countries that try to imitate genuine FR treated fabrics, but reputable suppliers have their products tested and pass the fire-resistance standards after 50, 75 or even 100 washes.

Consider using a specialist detergent designed for synthetic fibres.

iii. Stretch

Elastane (also known as spandex and lycra) is made from segmented blocks of copolymers containing randomly coiled, long, and liquid soft segments. This allows for movement in a linear direction. Elastane can stretch up to 4-7 times its length with excellent elastic recovery and it is stronger than rubber. Clogger’s stretch fabrics have elastane blended with other fibers to provide stretch for better ease of movement.

Elastane does need to be treated carefully. Fabrics with stretch have elastane and should be only be washed at luke warm / low temperatures (30 C / 90 F) and gentle agitation to maintain stretch and ensure that the elastic recovery is maintained over time.

Also, do not use laundry detergents with bleach or fabric softener as these chemicals damage elastane.

iv. Technical coatings and finishes

It is important to clean Clogger Chainsaw pants and chaps for long term performance especially when it relates to the coating used.

Most outer fabrics have some form of finish to the fabric and the most common finish used widely in fabrics today is DWR, which stands for Durable Water Repellent finish.

DWR is a finish that impregnates the fabric with a wax-like substance that causes water to bead up and run-off rather than soak into the fabric. Think of water off a duck’s back! As well as shedding water a DWR finish helps to reduce staining.

There are many different types of DWR finishes, wax/hydrocarbon derivatives, silicones and the flourides. By far the most common are the fluorides but there is an increasing awareness of the toxicity of these chemicals. There are some types of banned Flouride finishes. Clogger products are moving towards having zero fluoride-based DWR finishes.

All of these DWR finishes do wash out over time and dirt, oils and abrasion can reduce their performance. Once this happens, the outer layer will soak up moisture and cling to your skin. There are many products designed to rejuvenate a DWR finish. Most require drying with high heat to be effective though. The exception is Nikwax. Make sure that you follow each products instructions for good results.

In addition to DWR, polyester or nylon can also have a Polyurethane (PU) coating on the inside. This is an almost invisible film that gets laminated to the back of the fabric to provide a membrane that is impervious to water and oil. Apparel with a PU coating must get treated with care. Excessive agitation and hot temperatures when washing may cause delamination or cracking. Do not use a dryer. Line drying out of direct sunlight is best.

2. Washing

Washing is vital to maintain and clean Clogger chainsaw protective pants and chaps. Chainsaw protective apparel is similar to athletic gear so many of the same principles in cleaning these can be applied.

a. Pre wash

i. Preparing the garment

Some initial steps can reduce the risk of damage to the machine or garment

- Pull out the pockets and remove any wood chips and other loose external debris

- Close all the zippers (pockets, main centre zipper).

- Inspect outer fabric for any small tears for repair after cleaning.

ii. Removing contaminants

Excess dirt

If the pants or chaps are very dirty, take these extra steps.

- Soak in a bin or bucket with liquid soap and warm water

- Hose the outer to remove exterior dirt (do not use high pressure washers)

Pitch and sap

Remove pitch or sap by gently scraping off as much as you can without touching the fabric and then apply rubbing alcohol with a cotton ball until it lifts off.

Oil and other hydrocarbons

When the apparel is heavily contaminated with oil, soot, grease or other hydrocarbon contaminants, use Citrosqueeze or similar to clean. Citrosqueeze is a low risk product to use with extensive testing on a variety of materials.

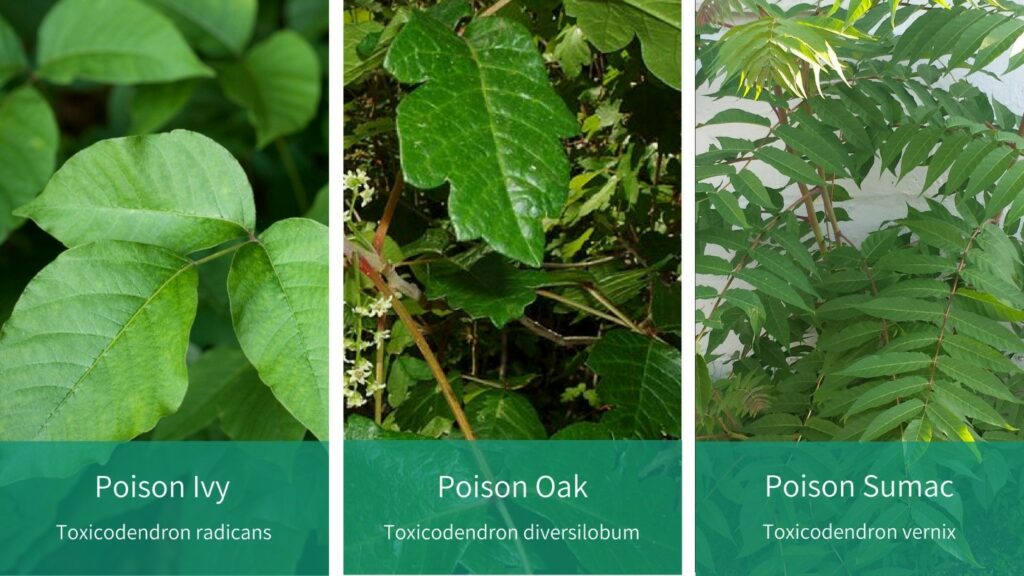

Poison ivy and poison oak

Poison Ivy and Poison Oak secrete an oil called urushiol, which transfers to clothing or skin simply by brushing against the leaves. This oil causes a very painful rash and unfortunately it is very sticky and remains active for years. If clothes are not cleaned thoroughly, you could touch the clothes 2 years later and feel the effects.

If your garment should come in contact with Poison ivy or Poison oak, there are several specific steps to take to thoroughly clean the garment:

- Carefully remove contaminated clothing and put in a sealed bag.

- Use gloves, preferably disposable otherwise you will have to wash the gloves too.

- Prepare the washing machine by opening the lid, pouring in the detergent and have it right ready to start washing. This will ensure that you don’t have to touch any of the machine surfaces with contaminated gloves.

- Using gloves again, take the clothes out of the bag and spot treat the areas with a specially formulated poison ivy oil remover such as Tecnu and Zanfel.

- Transfer to the washing machine. Wash without any other clothing items as they could get contaminated. Perform at least 3 if not 4 wash cycles to make sure that the urushiol is completely removed.

- Dispose of the bag responsibly

b. Choosing the right laundry detergent

For products with a DWR outer:

Choose soap that is specifically designed for washing garments with water repellent finishes.

We recommend Nikwax Tech Wash.

For all other products:

- Use a specialist liquid detergent designed for synthetic, water resistant apparel .

- Do not use powder or liquid clothes detergents or products that contain bleaches. Depending on the fibre origin, bleaches can affect the outer fabric reducing its life and is likely to cause colourant loss.

- Do not use fabric softeners or perfumed products as these can contain waxes or oils or can be hydrophilic (water-absorbing). This may reduce the breathability of the outer fabric and negatively affect the ability to repel moisture and effect stretch.

- If you use standard laundry detergent, make sure you rinse the garment a second time to remove any residues.

c. Washing machine settings

Wash your garments on a warm cycle with a temperature of around 30°C /90F. Use a gentle agitation setting, e.g. “Permanent press”. If possible, choose a cycle that rinses the garment twice to remove any oil and chemical residue left by the laundry soap.

3. Drying

As you maintain and clean Clogger chainsaw pants and chaps, drying is a key step. It is tempting to just use a drier but this is risky even at low temperatures both from a safety and product performance perspective.

- The recommended method for drying is to line dry. It is good practice to make sure this is out of the sun to prevent UV damage to the outer.

- Do not tumble dry. We specifically exclude tumble drying on our wash labels. While some garments can be tumble dried on a low heat, gentle cycle, it is not recommended especially for products with Arrestex HP chainsaw fabric and stretch so we have excluded this method from all products.

- Avoid direct sunlight. As mentioned before, any products made using fabrics with a PU coating ( Lower half of the ascend pant; Defenderpro chaps) must be line dried out of direct sunlight as excessive heat can cause the PU coating to crack.

- Be very careful if drying garments in front of a fire or other heat source. Ensure it is far enough away to not be excessively heated, or in other words only use gentle radiant heat. Check the surface temperature regularly to ensure that it is not overheating.

4. Storage

Proper storage is vital to keeping your Clogger pants and chaps in good condition. The products are an investment so at least treat them as well as your everyday apparel.

Store out of direct sunlight. Be careful leaving garments in a closed vehicle in hot sun as the temperatures may reach a point where the chainsaw fabric starts to shrink.

Hang up if possible. With chaps, make sure that they will not have other heavy objects placed on top that could break the buckles.

5. Product Specific Instructions

We have set out specific instructions so you know exactly how to maintain and clean Clogger chainsaw pants and chaps that you own. Most recommendations are very similar but there are differences that are important.

Zero Trousers

Zeros have a high tenacity stretch nylon outer with a DWR coating, abrasion resistant sections and a cut-resistant panel, made from UHMWPE fibres on the back of the right calf. The upper fabric also includes Nilit Breeze (Grey Zeros) or Coolmax (Orange Zeros). The chainsaw fabric uses Arrestex HP so includes UHMWPE fibre.

Pre wash:

Sap removal – Rubbing alcohol

Oil and hydrocarbon removal – Citrosqueeze

Close all zips

Wash cycle: Permanent press / Synthetic / Delicate wash

Water temperature: Max 40 C / 105 F

Detergent: “Free and Clear” Liquid (No bleach/No fabric softener) / Detergent for synthetic fabrics preferred e.g. Nikwax Tech Wash

DWR reviver: Nikwax TX.Direct Wash in

Drying: Air dry out of the sun

Ascend Trousers

Ascends have a stretch nylon outer with a DWR coating and abrasion resistant sections at the lower leg with PU coating to make these pants waterproof below the knee. The chainsaw fabric uses Arrestex HP so includes UHMWPE fibre.

Pre wash:

Sap removal – Rubbing alcohol

Oil removal – Citrosqueeze

Close all zips

Wash cycle: Permanent press / Synthetic / Delicate wash

Water temperature: Max 40 C / 105 F

Detergent: “Free and Clear” Liquid (No bleach/No fabric softener) / Detergent for synthetic fabrics preferred e.g. Nikwax Tech Wash

DWR reviver: Nikwax TX.Direct Wash in

Drying: Air dry out of the sun (using a dryer is not recommended for apparel with PU coatings)

DefenderPRO Trousers

DefenderPROs have a stretch Nylon outer with DWR. The chainsaw fabric uses Arrestex HP so includes UHMWPE fibres.

Pre wash:

Sap removal – Rubbing alcohol

Oil removal – Citrosqueeze

Close all zips

Wash cycle: Permanent press / Synthetic / Delicate wash

Water temperature: Max 40 C / 105 F

Detergent: “Free and Clear” Liquid (No bleach/No fabric softener) / Detergent for synthetic fabrics preferred e.g. Nikwax Tech Wash

DWR reviver: Nikwax TX.Direct Wash in

Drying: Air dry out of the sun

Defender Trousers (New Zealand / Australia / Japan only)

Defender trousers are made using a polyester/cotton outer at the front and a breathable nylon at the rear. The chainsaw fabric is Arrestex with no cut-resistant fibres.

Pre wash:

Sap removal – Rubbing alcohol

Oil removal – Citrosqueeze

Close fly zip

Wash cycle: Permanent press / Synthetic / Delicate wash

Water temperature: Max 40 C / 105 F

Detergent: “Free and Clear” Liquid (No bleach/No fabric softener)

Drying: Air dry out of the sun

Zero Chaps

Zero chaps have a high tenacity nylon outer with DWR. The chainsaw fabric uses Arrestex HP so includes UHMWPE fibres.

Prewash:

Sap removal – Rubbing alcohol;

Oil removal – Citrosqueeze

Wash cycle: Permanent press / Synthetic / Delicate wash

Water temperature: Max 40 C / 105 F

Detergent: “Free and Clear” Liquid (No bleach/No fabric softener) / Detergent for synthetic fabrics preferred e.g. Nikwax Tech Wash

DWR reviver: Nikwax TX.Direct Wash in

Drying: Air dry out of the sun

DefenderPRO Chaps

DefenderPro chaps have a high tenacity nylon outer with a PU waterproof coating. The chainsaw fabric uses Arrestex HP so includes UHMWPE fibres.

Prewash:

Sap removal – Rubbing alcohol

Oil removal – Citrosqueeze

Wash cycle: Permanent press / Synthetic / Delicate wash

Water temperature: Max 40 C / 105 F

Detergent: “Free and Clear” Liquid (No bleach/No fabric softener) / Detergent for synthetic fabrics preferred e.g. Nikwax Tech Wash

Drying: Air dry out of the sun (using a dryer is not recommended for apparel with PU coatings)

C8 Chaps

C8 Chaps have a polyester outer. The chainsaw fabric is Arrestex with no cut-resistant fibres.

Prewash:

Sap removal – Rubbing alcohol

Oil removal – Citrosqueeze

Wash cycle: Permanent press / Synthetic / Delicate wash

Water temperature: Max 40 C / 105 F

Detergent: “Free and Clear” Liquid (No bleach/No fabric softener)

Drying: Air dry out of the sun

Fire Resistant (FR) pants – Wildfire and Arcmax

Arcmax – Designed for tree workers facing a risk of fire or arc flash, these trousers finally give you true protection with all parts fully fire resistant including the chainsaw protection material. All components fire resistant, including outer fabric, chainsaw protective fabric and lining. The chainsaw fabric uses Arrestex FR.

Wildfire – Designed for wildland fire crews working in the heat, Wildfire chainsaw pants are designed to be easier to work in with 4 way stretch and a tough FR outer. All components fire resistant, including outer fabric, chainsaw protective fabric and lining. The chainsaw fabric uses Arrestex FR.

Prewash:

Sap removal – Rubbing alcohol

Oil removal – Citrosqueeze

Empty pockets of sawdust and debris. Inspect and close all zips.

Wash cycle: Permanent press / Synthetic / Delicate wash

Water temperature: Max 40 C / 105 F

Detergent: “Free and Clear” mild Liquid (No bleach/No fabric softener)

Drying: Do not tumble dry. Air dry out of the sun

6. Inspection and Maintenance

Tree work provides a tough environment for apparel. Good maintenance practices including regular washing as outlined above will extend the life of your Clogger chainsaw protective pants and chaps.

a. Rips and tears

Repair any small tears and holes as they occur if possible because small rips become large rips. Watch the video below:

At times a rip may be in a position that is hard to repair or be too major to repair with a home sewing kit. Consider taking the garment to an alteration service or returning the garment to the manufacturer for repair. If you are the other side of the world then the cost of freight may not warrant sending a garment back. Clogger are able to send you additional patches or larger pieces of fabric if needed.

One very important point when repairing garments is to never stitch through the chainsaw protective fabric. At times this makes it very hard to carry out repairs which is why hand stitching is really the only option in a lot of cases. The reason for this is that the fibres design is to pull out at the contact point of a moving chain. Stitching through the pad locks these fibres in place so they won’t perform as intended in an accident.

If attempting to use glue behind a tear in the outer fabric, ensure that no glue gets on to the chainsaw fabric as this will also lock up the fibres. Techniques like pushing a piece of paper under the outer to prevent glue reaching the chainsaw fabric can be effective.

b. Burns

Exhaust burns are a very common issue. Unfortunately, a burn is likely to mean that the pants or chaps need to be retired. Heat high enough to melt the outer will very likely have fused the top layers of the chainsaw fabric. A light touch that just damages the outer may mean that the product can still be used though there is still a risk that the chainsaw fabric is compromised even though you can not see the damage.

With the Arcmax fire resistant pants and chaps, the outer and fabric will likely be still fully functional after an exhaust burn.

c. Damaged seams

When inspecting garments for damage, check the main seams for any stitches coming undone and repair before they get worse.

One area that is susceptible for seam breakage on trousers is the rear centre seam and the crutch seam running from front to back. This seam comes under a lot of strain with movement in the trees and on the ground. In addition the way that the fabrics get cut to form these curves can cause uneven stretching and give. Additionally with the weight of chainsaw garments, they tend to slip low which causes even greater pressure on these seams. If stitches do start coming undone, run over these seams with a sewing machine immediately.

The seam will very quickly continue to open and possibly the fabric will start to tear.

d. Zips

Another very important area to inspect and maintain are the zips. The working environment is very hard on zips with all the sawdust, dirt, tree sap, oils etc.

Most zips used in Clogger garments are a medium size (measured across the teeth), coil type zip and are ‘reversed’. This means the teeth are on the inside surface and the 2 halves of the zipper tape butt together on the outside to form a barrier to the entry of sawdust.

Tips for ensuring your zips continue to work:

Don’t force the slider. There may be that some small slivers of wood caught in the coils which are stopping it from engaging. The pocket bag fabric or the flap of fabric behind the fly zip may get caught in the slider. There is always a reason why a slider won’t move freely so check it out and remove the cause first. Always gently back the slider off with as little force as possible then look for the obstruction.

Don’t place excessive strain on the zips. Putting trousers on or taking them off with the zip only partly down places strain on the teeth and slider. When the slider is at the bottom of the zip the strain gets taken by the fabric and the seams. Also, make sure that the pants are large enough to allow for easy movement. If the pants are tight, go up a size.

Clean the zips well. As mentioned before, oils attract dust so clean any oily substances off the zips immediately. Washing the pants will also clean the zip but always make sure that the zips are closed before washing.

Simple maintenance steps

Problem 1: Zip slider goes up but the zip pulls apart with movement.

A zip slider has two halves joined at the front. If these 2 halves get bent apart slightly or the coils worn, the trailing edges of the slider doesn’t put enough pressure on the teeth to properly lock them. After getting the slider back to the start, a careful squeeze on the two halves at the trailing edge with some pliers may rectify this. Be careful though as an over-squeeze could clamp the slider on to the zip!

Problem 2: Zip slider is hard to pull up.

First, check for any dirt or dust in the zip coil. Use a clean brush to clear any materials. Then lubricate the zipper teeth with graphite e.g. a soft pencil, regularly. Rub the pencil is on the ends of the coils at the outside edges. These outside edges are the critical points that the slider pushes against to close the zip. Don’t use oily substances for lubrication as they attract dust which can become an agent for abrasion.

Problem 3: The zip has failed.

Zips can be repaired in two ways. First, you can unpick the bottom of the zip and replace the slider. Alternatively, the whole zip can be replaced. The preventative measures above are clearly preferable to replacement.

d. Chaps fastenings

The fastenings of chaps are an integral part of the safety of the product. The design is to hold the pad in place on your leg: missing or damaged buckles won’t buckle up then the garment may not work in the event of an accident.

Replace damaged buckles immediately. Clogger can supply spare buckles either on their own or assembled on to a strap. Your local canvas shop should be able to carry out this repair work.

- If the male half needs replaced, the foldover at the end of the webbing can be undone. Remove the old buckle and thread the new one on. Turn over the end you undone in the beginning and secure it to stop the buckle coming off.

- If it is the male side and the webbing has become damaged as well or there is damage to the female side, then the old webbing needs to be cut off preferably searing the cut ends carefully with a lighter. Place the new strap in position and stitch on well with 2 rows of stitches, backtacking over the strap. Use a 3mm (1/8th”) stitch length to ensure there are plenty of stitches holding it and use a size 36 (tex40) thread.

7. Retirement of Chainsaw Pants and Chaps

If the following situations occur, consider retiring your Clogger chainsaw protective pants and chaps:

- Numerous holes and cuts on the outer. Extensive damage to the outer fabric exposes the chainsaw fabric to direct wear as well as allowing the build-up of bar oil and sawdust/wood chips that can reduce the level of protection.

- Exhaust burns. In most cases, the burn effects more than just the outer and will have damaged the chainsaw fabric. Arcmax FR chainsaw pants and chaps will likely not be severely affected and can stay in service.

- Improper repairs. Sewing through the chainsaw fabric prevents the fibres from moving inhibiting their function and therefore reducing the level of cut protection.

- Evidence of incorrect cleaning. The use of bleaches may impact the cut resistance of the chainsaw fabric fibres. Using high pressure power washers or heavy duty machine wash and drying cycles can also damage the cut resistant fibers and the chainsaw fabric structures. If the chainsaw fabric is bulking up at the bottom of the garment or appears to be migrating from where it should be, do not use.

- Evidence of incorrect drying processes. If chainsaw fabric feels rigid or has shrunk excessively it maybe an indication that excessive heat was used to dry the garment. This may have partially melted the cut-resistant fibres.

- Significant damage to the chainsaw fabric. Any chainsaw cut that has pulled out chainsaw fabric fibres. Chainsaw fabric is only effective for the first cut. After that the fabric structure gets disrupted as fibres get extracted from below the cut, above the cut and to each side of the cut. A second cut will most likely be ineffective.

Fire resistant garments

A special mention regarding fire resistant garments. The outer covering is the first line of defense in the event of an arc flash or coming in touch with hot embers when fighting a wildland fire. Open holes in the outer fabric of these garments may severely affect the performance of the garment in providing protection. While our FR garments get made using Arrestex FR which is in itself fire-resistant, its primary design is an open weave to be chainsaw protective not to prevent a fire hazard. Repair any holes in the outer fabric immediately with the same or similar FR material as the original.

When retiring garments, dispose of them responsibly.

8. Conclusion

How well you maintain and clean Clogger chainsaw pants and chaps directly correlates as to how long they last. If you treat them right, they will last the distance. Inspecting is important because the earlier you notice any problems the quicker you can address them and get longer life from your investment.

Want to learn more about selecting the best chainsaw safety gear?

Check out our ultimate guide.

Have any other questions about chainsaw pants and chaps cleaning, maintenance and care?

We would love to hear your questions or feedback below.